Research Projects

Titanium

In-situ characterisation of the high temperature deformation micromechanics in dual-phase Ti alloys

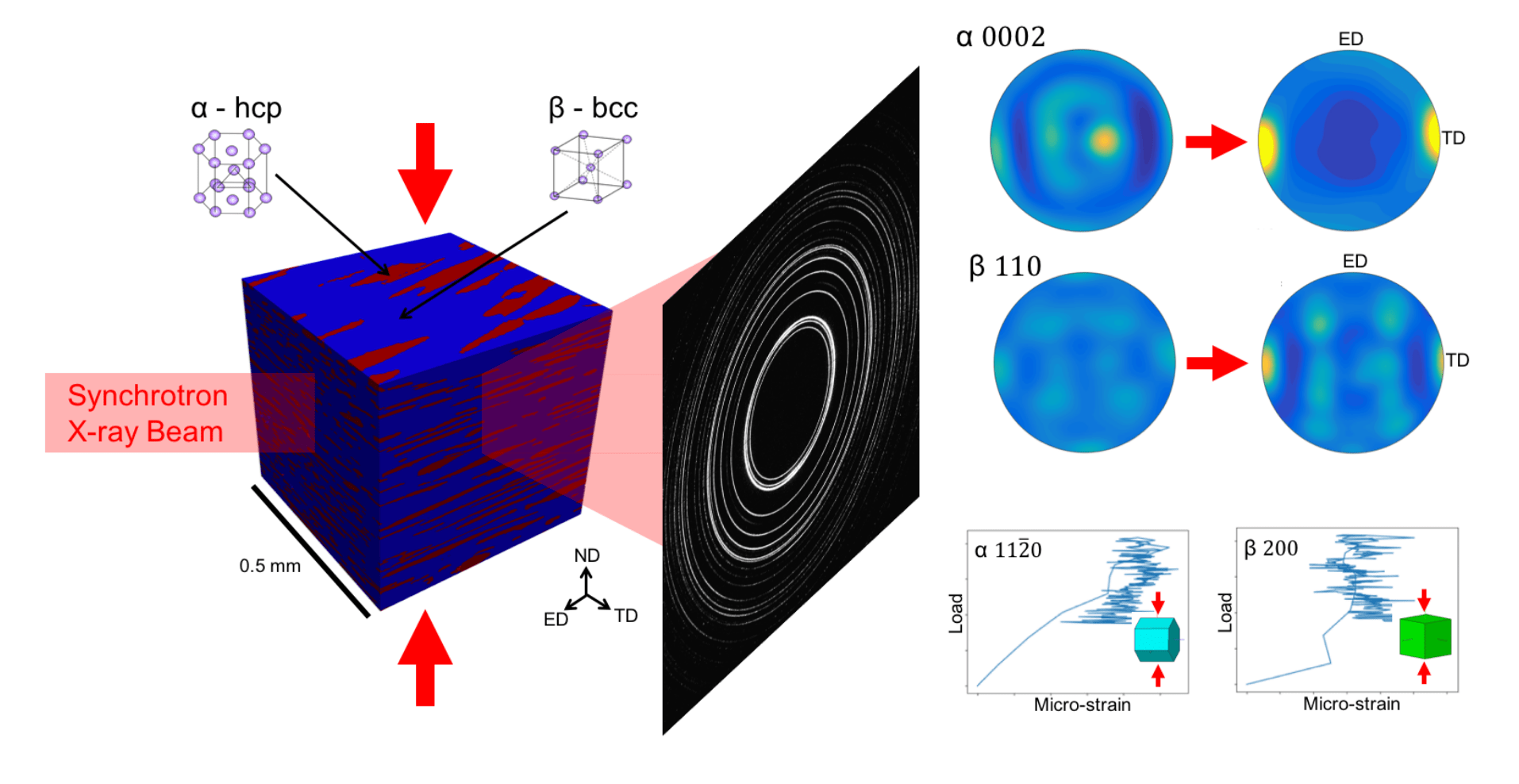

Microstructure and crystallographic orientation (texture) in dual-phase Ti-6Al-4V materials is controlled by thermo-mechanical processing during manufacture, offering a unique combination of properties to tailor the performance requirements of aerospace components. Nevertheless, material evolution is difficult to predict in dual-phase alloys, due to complex multi-scale interactions between the α (hexagonal-close-packed, hcp) and β (body-centred-cubic, bcc) phases, occurring during both deformation and phase transformation. In this project, we aim to improve our understanding and the predictions of processing simulations by studying the deformation of these alloys in-situ, observing microstructure evolution throughout entire thermo-mechanical cycles.

We are developing in-situ experiments using synchrotron X-ray diffraction (SXRD) and neutron diffraction, using new simulation rigs, to provide time-resolved data that will be used to measure the dynamic interactions and micromechanical properties of the two phases.

To date, an SXRD experiment at Diamond Light Source was conducted with a novel setup of an electro thermal mechanical tester (ETMT) mounted on the I12:JEEP (Joint Engineering, Environmental and Processing) beamline, able to deform matchstick Ti-6Al-4V samples in tension at high temperature (850ºC – 950ºC), whilst continuously monitoring diffraction ring patterns on a fast acquisition 2D detector.

The determination of internal lattice strain evolution, dynamic phase transformation and grain reorientation, is being supported through the development of new data analysis scripts in the IPython computing environment, along with new methods for automating texture calculation using the MAUD (Materials Analysis Using Diffraction) software. The project will also include design of a high temperature compression rig for the I12 beamline, providing even sample heating and a controlled geometry, with the aim to deform miniature cuboid samples in plane strain for precise measurements during simulated forging.

The bulk Ti-64 material properties will be verified using neutron diffraction at ISIS, on the ENGIN-X and GEM beamlines, with experiments planned to improve data acquisition speeds of the current methods. The long-term goal in LightForm is to use these in-situ results to establish physically-based predictive microstructure evolution models, to enable optimisation of the fabrication route and support tailoring the properties of two-phase Ti alloys to meet the demands of the aerospace industries.