Research Projects

Aluminium

Improving the Hot Form Quench (HFQ) process in aluminium alloys

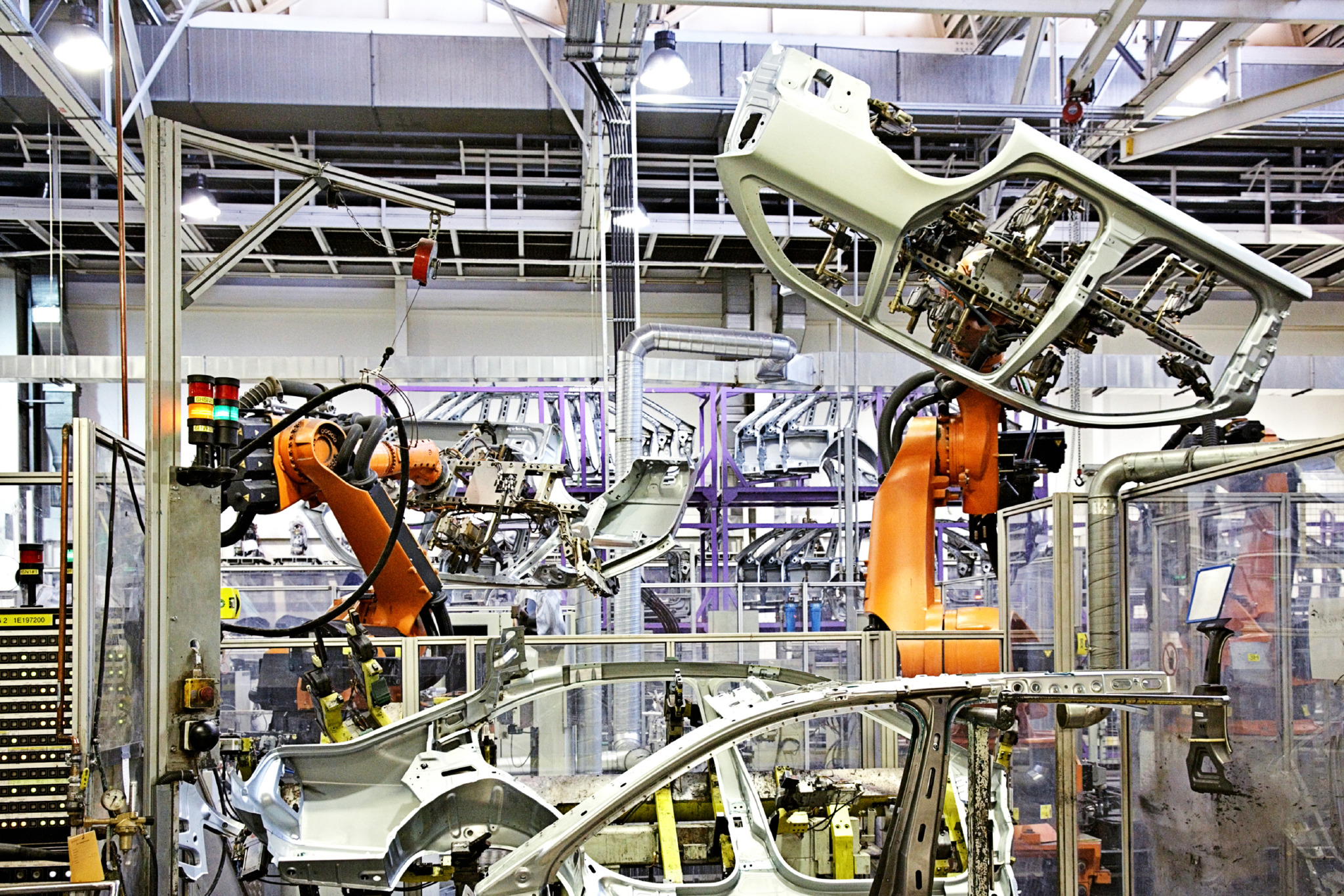

Hot Form Quench (HFQ) is a process in which stamping and heat treating are combined in a single operation to produce complex-shaped components from high-strength aluminium alloys. In the HFQ process aluminium alloy sheets are solution heat treated then pressed to shape while still hot. The part is quenched in the die followed by artificial thermal ageing to the peak strength T6 condition. This process allows for a greater draw depth which significantly reduces assembly operations, tooling design and design operations as well as improving the strength of the material. As a result thinner material can be used, reducing vehicle weight and CO2 emissions while reducing running costs to the transport industry. However, optimisation of the different steps involved in the HFQ process is crucial to obtain high-performance components at sustainable cost.

This project is aimed at studying the effect of different post-forming ageing treatments on the microstructure, mechanical properties and corrosion resistance of HFQ parts. For this purpose, commercially produced HFQ automotive parts have been supplied by Impression Technologies Ltd. The microstructure and performance of different regions of these parts are being examined to understand the interaction between the forming process variables (temperature and local strain history), microstructure and performance. For the microstructural characterisation, a combination of complementary techniques, including scanning and transmission electron microscopy is being used.